In today's fast-paced manufacturing sector, staying connected and maintaining efficient operations is more critical than ever. Recent statistics highlight some of the challenges faced by the industry:

- A staggering 54% of U.S. manufacturers report lacking a unified view of their plant floor information.

- Up to 40% of profits can be lost due to unplanned downtime.

- Annually, $51.1 billion is paid to U.S. workers injured on the job, with 500,000 workers injured or ill from the 12 million manufacturing employees.

These figures underscore the urgent need for effective communication and safety solutions in manufacturing environments. Here's how digital radios are transforming the manufacturing landscape:

Hear Clearly Over the Clamor

Manufacturing floors are notoriously noisy. Digital radios cut through the noise, ensuring clear communication between team members. This clarity is vital for coordinating operations and responding swiftly to any issues that arise.

Receive Automatic Malfunction Alerts

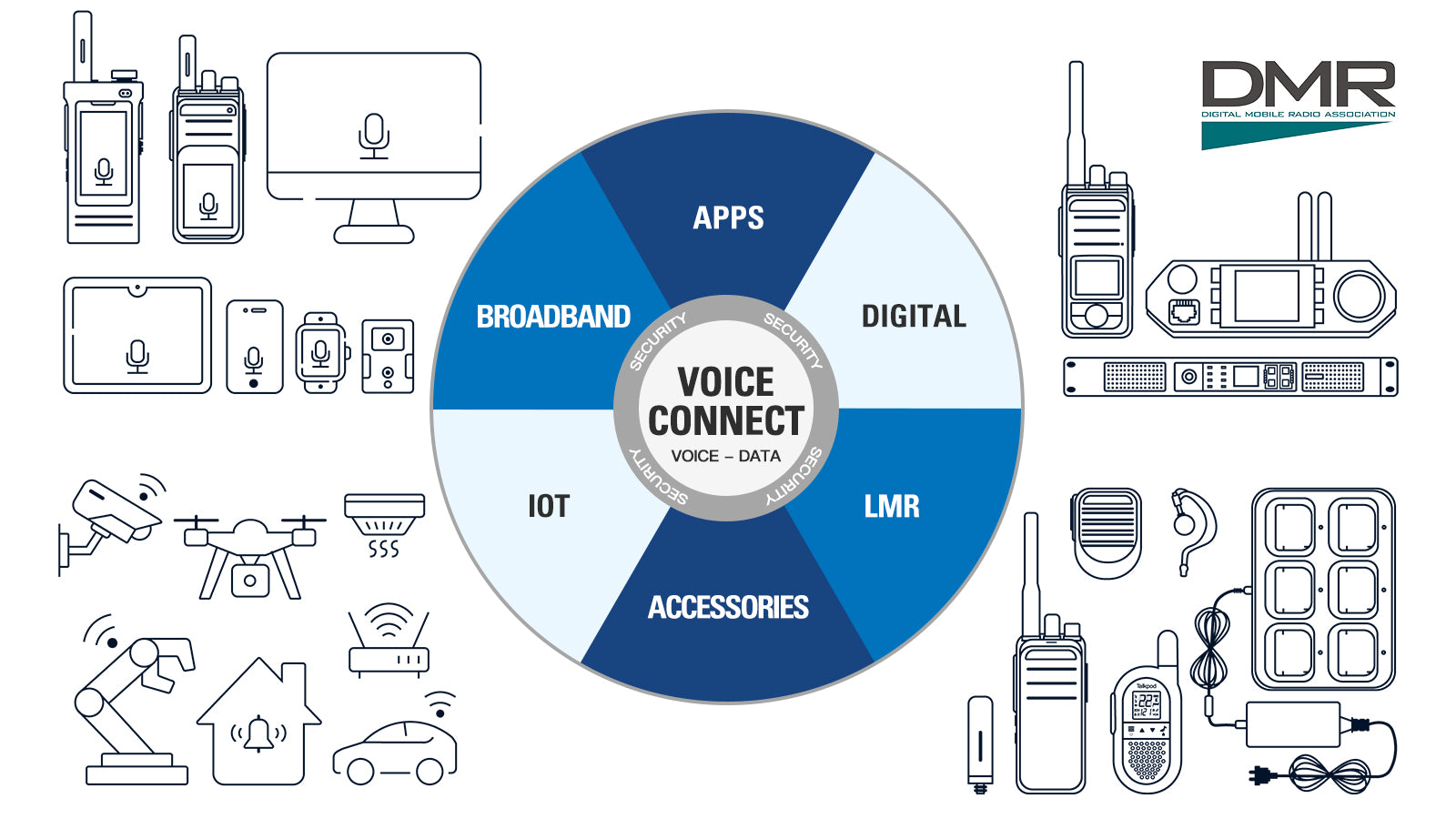

Digital radios equipped with IoT capabilities can receive alerts directly from machines on the shop floor. This immediate notification of malfunctions allows for quicker response times, reducing downtime and maintaining productivity.

Instant Communication to All

With digital radios, messages can be broadcast instantly to all devices, whether they're digital radios or cell phones. This ensures that everyone, from the plant floor to the front office, stays informed and aligned, enhancing collaboration and efficiency.

Protect Workers

Digital radios offer features designed to enhance worker safety:

- One-Touch Ergonomics: Simple, user-friendly interfaces allow for quick and easy communication.

- Emergency Button: Workers can alert others instantly in case of an emergency, speeding up response times.

- Man Down Feature: This feature detects if a worker has fallen and sends an automatic alert.

- Lone Worker Feature: Regular check-ins ensure that lone workers are safe and responsive.

- Prioritization: Critical communications can be prioritized to ensure they're heard first.

- Clear Audio: Ensures messages are understood the first time, reducing miscommunications.

Power for the Full Shift

Long battery life means digital radios last through demanding shifts, ensuring workers stay connected from start to finish without needing to recharge during critical times.

Conclusion

The manufacturing sector's efficiency and safety are significantly enhanced with the adoption of digital radios. By providing clear communication, instant alerts, and robust safety features, digital radios help reduce downtime, prevent profit loss, and, most importantly, protect workers. As the industry continues to evolve, the integration of digital communication tools will be key to staying competitive and maintaining a safe, efficient operational environment.