HIGH QUALITY, EXCEPTIONAL RELIABILITY,AND GLOBAL SUSTAINABILITY

Radio Communication Experts

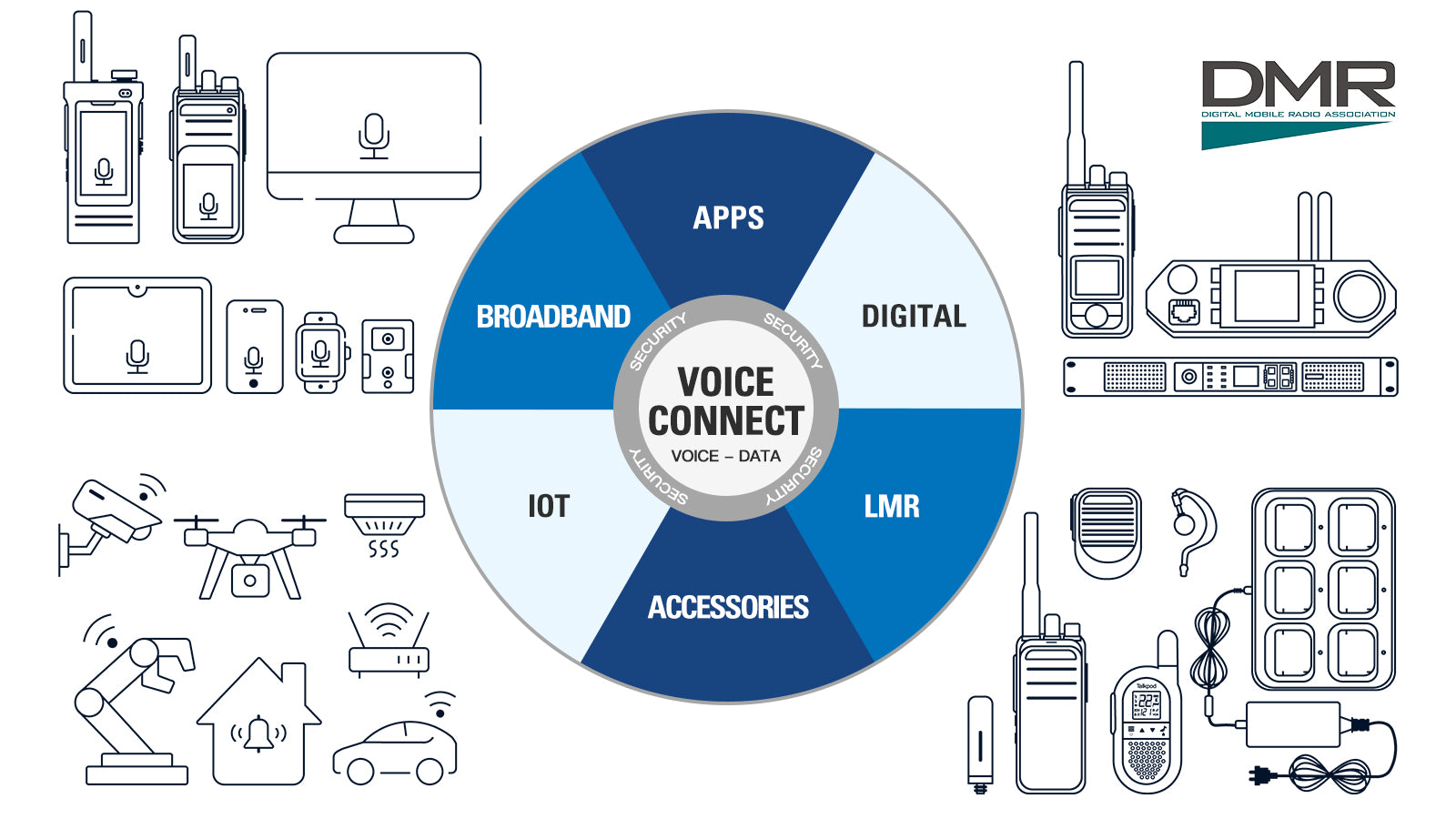

Talkpod Technology, based in Shenzhen, China, is a premier manufacturer of wireless communication products. Since 1991 we have built a reputation for delivering innovative and reliable communication solutions, including DMR, PoC, LMR, HAM, PMR446, FRS, GMRS radios, and aviation communication products.

Quality and Reliability

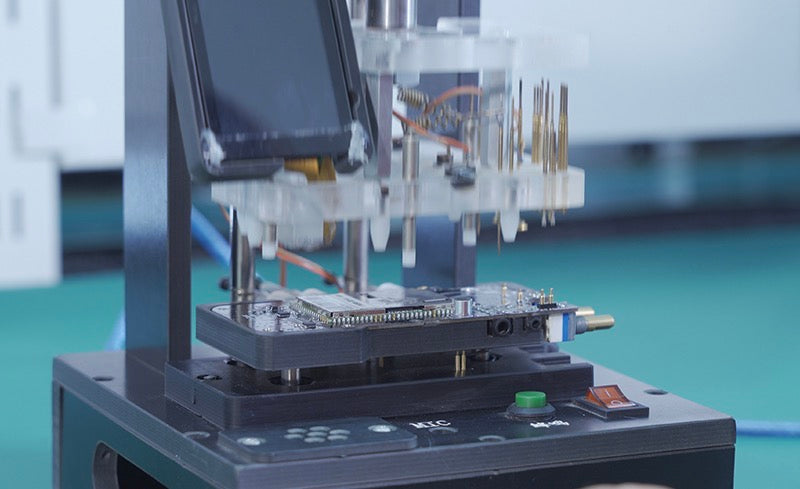

With decades of engineering and production excellence, every Talkpod product embodies our commitment to quality. Utilizing state-of-the-art equipment, our radios undergo rigorous in-house testing as well as environmental assessments to meet and exceed international standards. Our products are also compliant with global directives, including the European RoHS directive.

Global Standard Quality

Talkpod maintains strict control over our manufacturing processes to ensure the highest quality standards. Our production facilities in China employ advanced manufacturing systems, allowing us to produce a diverse range of wireless communication products with precision and efficiency.

Talkpod, a World Brand

Today, Talkpod is recognized as a reliable name in the two-way radio industry worldwide. Our land mobile radios are trusted by numerous professional organizations, both public and private, across various industries. We are proud to support critical communication needs around the globe.

Talkpod's Worldwide Network

Talkpod products are available in over 50 countries, supported by an extensive international sales and service network. Our subsidiaries in the US, Europe, and Asia ensure that we are always close to our customers, ready to provide support and service.

TALKPOD’S QUALITY POLICY

Talkpod is committed to quality.

We strive to earn your trust by consistently providing dependable products and services, on time delivery, and reliable support for all your mission and business critical applications.

We foster a culture of innovation and accountability that ensures our quality management system is continually evolving to meet your highest expectations. Our reputation and quality heritage represent our continued commitment to earn your trust as a complete solution provider.

To Secure a Quality Level Trusted by Our Customers

Talkpod Technology is dedicated to continuously improving our production systems to deliver safe and high-quality products. Our commitment to compliance with ISO9001:2015 ensures that we understand and meet the requirements for quality and customer satisfaction. We set and review quality targets regularly, striving for continuous improvement through efficient work practices and a clean, organized environment.

Commitment to High Productivity and Quality

Talkpod operates with a philosophy of high productivity and superior quality across all operations. Our facilities are equipped to meet the highest standards, ensuring that every product we produce meets our stringent quality requirements.

MEETING GLOBAL STANDARDS

Talkpod leverages its technical expertise and extensive know-how to develop and manufacture products that comply with a wide range of international testing standards, ensuring that we meet the diverse needs of our customers.

Below are some of the technical standards Talkpod radios meet or exceed. Different models meet different standards based on customer needs.

TIA/EIA603 technical standard compliance

TIA/EIA603 is the Land Mobile FM or PM Communications Equipment Measurement and Performance Standards.

TIA/EIA TSB102 is theTelecommunications System Bulletin for Digital C4FM/CQPSK

Transceivers Mesuement Method.

The Electronic Industries Alliance (EIA, until 1997 Electronic Industries Association) is a trade.

EN 300-086 technical standard compliance

This standard is intended to specify the minimum performance and the methods of measurement of radio equipment for use in the land mobile service.

Equipment and Systems (RES) Technical Committee of the European Telecommunications Standards Institute (ETSI).

FM intrinsically safe approved

FM approvals are intended to verify that the products and services described will meet stated conditions of performance, safety and quality useful to the ends of property conservation.

FM Approvals tests and approves electrical equipment in accordance with Approval Standards and/or American National Standards Institute (ANSI) standards.

Hazardous location electrical equipment testing is one of FM Approvals' largest

product categories.

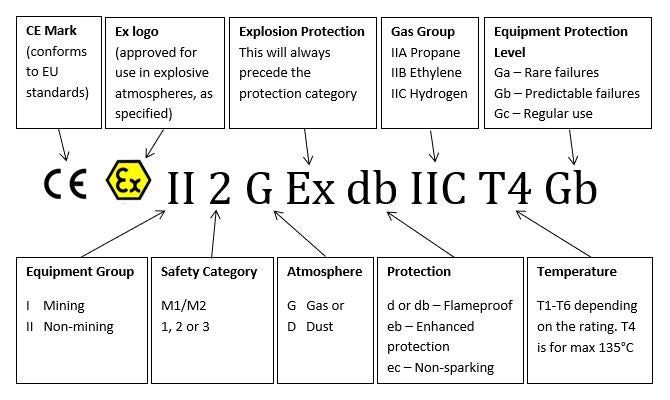

ATEX intrinsicallysafe approved

The ATEX Directive is a legal requirement in all European Union Member States if equipment is intended for use in potentially explosive atmospheres.

The ATEX Directive is a legal requirement in all European Union Member States if an equipment intended for use in potentially explosive atmospheres

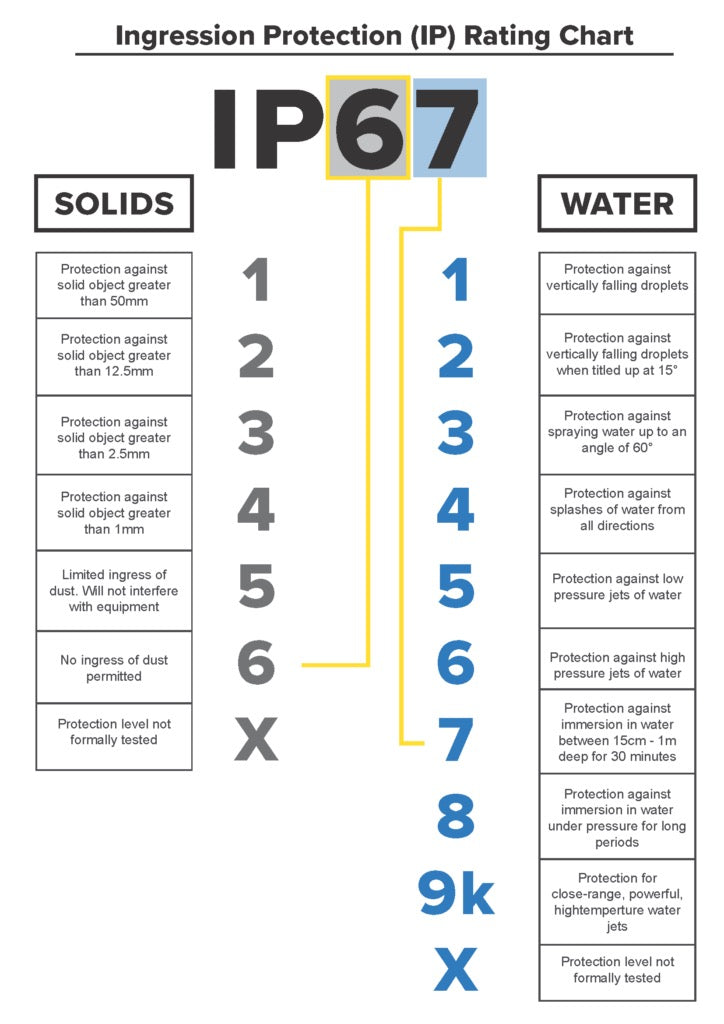

IP54, IP55, IPx7, IPx8 dust/water resistance and submersible compliance

International Standard IEC 60529 outlines an international classification system that describes the sealing characteristics of electrical equipment. It defines the level of protection provided by enclosures to prevent the ingress of foreign objects and moisture into the electrical equipment.

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes international standards for all electrical, electronic and related technologies.

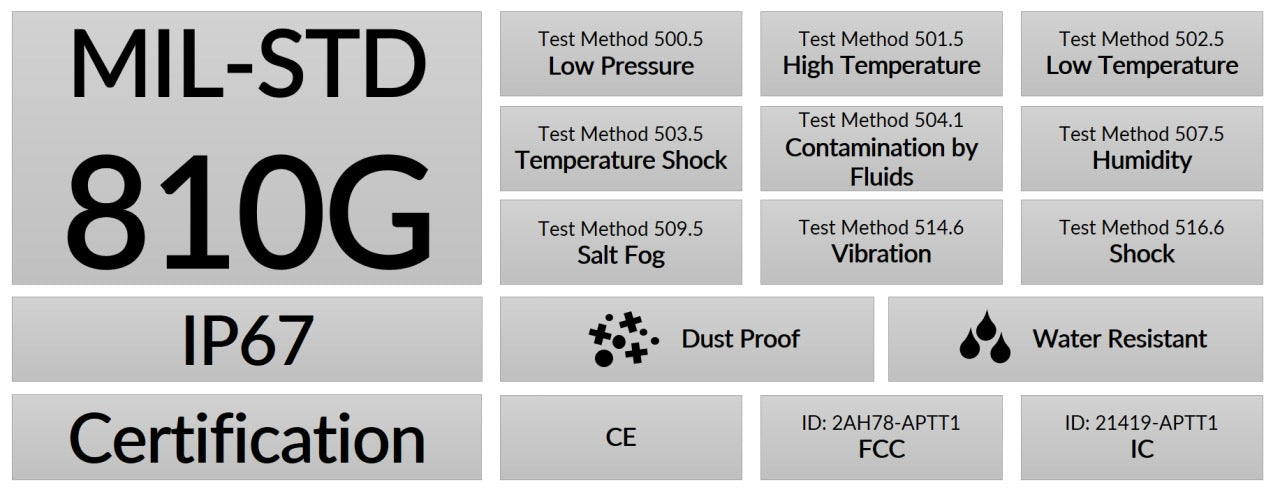

MIL-STD-810F environment testingstandards

The MIL-STD-810 series of standards are issued by the United States Army's Developmental Test Command to specify various environmental tests to prove that equipment qualified to the standard will survive in the field.

A United States Defense Standard, called a "MIL- STD”, is used to help achieve standardization objectives by the U.S. Department of Defense.

Talkpod designs its radios to comply with all relevant health, safety and environmental protection regulations to ensure the safety of users is maintained to the strictest standards.

Talkpod radios comply with the following Standards and Guidelines with regard to RF energy and electromagnetic energy levels and evaluation of such levels for exposure to humans.

FCC OET Bulletin 65 Edition 97-01

FCC OET Bulletin 65 Edition 97-01 Supplement C, Evaluating Compliance with FCC Guidelines for Human Exposure to Radio Frequency Electromagnetic Fields.

The Federal Communications Commission (FCC) is an independent United States government agency. The FCC was established by the Communications Act of 1934 and is charged with regulating interstate and international communications by radio, television, wire, satellite and cable. The FCC's jurisdiction covers the 50 states, the District of Columbia, and U.S. possessions.

The CE Marking Certifies

Talkpod radios have been tested and comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation.

CE version of Talkpod Radios which display the “CE” symbol on the serial number seal, comply with the essential requirements of the European Radio and Telecommunication Terminal Directive 1999/5/EC.

The CE Marking on a product is a manufacturer's declaration that the product complies with the essential requirements of the relevant European health, safety and environmental protection legislations, in practice by many of the Product Directives.

American National Standards Institute (C95.1-1992)

American National Standards Institute (C95.1-1992), IEEE Standard for Safety

Levels with Respect to Human Exposure to Radio Frequency Electromagnetic Fields, 3 kHz to 300 GHz.

As the voice of the U.S. standards and conformity assessment system, the American National Standards Institute (ANSI) empowers its members and constituents to strengthen the U.S. marketplace position in the global economy while helping to assure the safety and health of consumers and the protection of the environment.

IEEE Recommended Practice for the Measurement

American National Standards Institute (C95.3-1992), IEEE Recommended Practice for the Measurement of Potentially Hazardous Electromagnetic Fields– RF and Microwave.

A non-profit organization, IEEE is the world's leading professional association for the advancement of technology.

The IEEE name was originally an acronym for the Institute of Electrical and Electronics Engineers, Inc.

Today, the organization's scope of interest has expanded into so many related fields that it is simply referred to by the letters I-E-E-E (pronounced Eye-triple-E).

IP CLASSIFICATION CODES

Ingress Protection (IP) ratings are developed by the European Committee for Electro Technical Standardization.

International Standard IEC 60529 outlines an international classification system that describes the sealing characteristics of electrical equipment. The classification system defines the level of protection provided by enclosures to prevent the ingress of foreign objects and moisture into the electrical equipment.

The classification system uses the “IP” code, or “Ingress Protection” code, to define the level of seal. An IP number contains two numbers (i.e. IP67) in most instances which relate to the level of protection provided by an enclosure or housing. Either number may be shown as “X” (i.e. IPX6 / IP7X) to indicate the “X” part is not tested.

INTRINSICALLY SAFE TYPE APPROVAL

Organize content into multiple columns to share useful information to your customers about your products, values...

FM Intrinsically safe version

ntrinsically safe transceivers offer safety approved 2-way communication preventing explosion and fire hazard in specified hazardous areas.

What is FM Approval?

FM Approvals are intended to verify that the products and services described will meet stated conditions of performance, safety and quality useful to the ends of property conservation. The purpose of FM Approval Standards is to present the criteria for FM Approval of various types of products and services, as guidance for FM Approvals personnel, manufacturers, users and authorities having jurisdiction.

A number of Icom transceivers meet this regulation which display the “FM APPROVED” symbol as at left on the serial number seal, conform to intrinsically safe ratings of the FM Global Corporation.

The repair and maintenance of an FM approved transceiver can only be performed in an approved repair facility. The FM approval will be canceled if FM intrinsically safe radios are repaired anywhere else except in an approved facility.

There are versions that conform to intrinsically safe rating of the FM Approvals.

Intrinsically Safe: Class Ι, ΙΙ, ΙΙΙ, Division 1, Groups C, D, E, F, G

Nonincendive: Class Ι, Division 2, Groups A, B, C, D hazardous locations

Temperature Class: T3C

ATEX Intrinsicallysafe version

ATEX versions of the Icom transceivers which display the “EX” marking on the serial number seal.

The approval rating for these models is II2G Ex ib IIA T3.

PASSED MIL-STD-810F ENVIRONMENTAL TEST

Talkpod makes rugged products that have been tested to and passed the following MIL-STD requirements and strict environmental standards.

The purpose and procedure of each standard is briefly described in the following pages. Talpod performs MIL-STD testing in-house as well as with independent laboratories.

*The applied standards differ depending on model.

LOW PRESSURE (ALTITUDE) METHOD 500.4

Use low pressure (altitude) tests to determine if radios can withstand and/or operate in a low pressure environment and/or withstand rapid pressure changes.

Procedure I - Storage/Air Transport.

Procedure I is appropriate if the radio is to be transported or stored at high ground elevations or transported by air in its shipping/storage configuration.

Procedure II - Operation/Air Carriage.

Use Procedure II to determine the performance of the radios under low pressure conditions.

HIGH TEMPERATURE METHOD 501.4

Use high temperature tests to obtain data to help evaluate effects of high temperature conditions on radios safety, integrity, and performance.

Procedure I - Storage.

Use Procedure I to investigate how high temperatures during storage affect the radios (integrity of materials, and safety/performance of the radios).

Procedure II - Operation.

Use Procedure II to investigate how high ambient temperatures may affect radios performance while it is operating.

LOW TEMPERATURE METHOD 502.4

Use low temperature testing to measure how low temperature conditions during storage, operation, and manipulation affect radios safety, integrity, and performance.

Procedure I - Storage.

Use Procedure I to investigate how low temperatures during storage affect radios safety during and after storage, and performance after storage.

Procedure II - Operation.

Use Procedure II to investigate how well the radios operates in low temperature environments.

TEMPERATURE SHOCK METHOD 503.4

Use temperature shock tests to determine if radios can withstand sudden changes in the temperature of the surrounding atmosphere without experiencing physical damage or deterioration in performance.

Procedure I (Steady State)

Procedure I employs constant temperature at each of the extreme shock conditions because, in many instances, the thermal shock itself so outweighs the other thermal effects that the test may be performed using two constant temperatures.

SOLAR RADIATION (SUNSHINE) METHOD 505.4

To determine the heating effects of direct solar radiation on radios. And to help identify the actinic (photodegradation) effects of direct solar radiation.

Procedure I – Cycling (heating effects).

Use Procedure I to investigate response temperatures when radios is exposed in the open in realistically hot climates and is expected to perform without degradation during and after exposure.

RAIN METHOD 506.4

The purpose of this method is to help determine the effectiveness of protective covers, cases, and seals in preventing the penetration of water into the radios. Also the capability of the radios to satisfy its performance requirements during and after exposure to water.

Procedure I - Rain and Blowing Rain

Procedure I is applicable for radios which will be deployed out doors and which will be unprotected from rain or blowing rain.

Procedure III - Drip.

Procedure III is appropriate when the radio is normally protected from rain but may be exposed to falling water from condensation or leakage from upper surfaces.

HUMIDITY METHOD 507.4

The purpose of this method is to determine the resistance of radios to the effects of a warm, humid atmosphere.

Test duration of the minimum number of 48-hour cycles for this test is five. Temperature/humidity levels are 60°C and 95% RH

SALT FOG METHOD 509.4

The salt fog method is performed to determine the effectiveness of protective coatings and finishes on materials.

Use a 5 ± 1% salt solution concentration.

SAND AND DUST METHOD 510.4

These tests are performed to help evaluate the ability of radios to resist the effects of dust that may obstruct openings, penetrate into cracks, crevices, bearings, and joints and to evaluate the effectiveness of filters.

Procedure I - Blowing Dust.

Use Procedure I to investigate how susceptible radios is to concentrations of blowing dust (< 149 Pm).

IMMERSION METHOD 512.4

The immersion test is performed to determine if radios can withstand immersion or partial immersion in water and operate as required during or following immersion.

Procedure I - Immersion.

Procedure I (Immersion) primarily addresses leakage during immersion of encased radios.

Depth of immersion is 1m.

Duration of immersion is 30-minutes

VIBRATION METHOD 514.5

Develop radios to function in and withstand the vibration exposures of a life cycle including synergistic effects of other environmental factors, radios duty cycle, and maintenance. Although verify that radios will function in and withstand the vibration exposures of a life cycle.

Procedure I - General vibration.

Use Procedure I for those cases where a test item is secured to a vibration exciter and vibration is applied to the test item at the fixture/test item interface. Steady state or transient vibration may be applied as appropriate.

SHOCK METHOD 516.5

Shock tests are performed to provide a degree of confidence that radios can physically and functionally withstand the relatively infrequent, non-repetitive shocks encountered in handling, transportation, and service environments, and determine the radio's fragility level, in order that packaging may be designed to protect the radio's physical and functional integrity.

Procedure I - Functional Shock.

Procedure I is intended to test radios (including mechanical, electrical, hydraulic, and electronic) in its functional mode and to assess the physical integrity, continuity and functionality of the radios to shock. In general, the radios is required to function during the shock and to survive without damage to shocks representative of those that may be encountered during operational service.

Procedure IV - Transit Drop.

Procedure IV is intended for radios either outside of or within its transit or combination case, or as prepared for field use (carried to a combat situation by man, truck, rail, etc.). This procedure is used to determine if the radios is capable of withstanding the shocks normally induced by loading and unloading when it is outside of its transit or combination case, or inside its transit or combination case. Such shocks are accidental, but may impair the functioning of the radios.

OUR COMMITMENT TO YOU

Talkpod is committed to providing you with quality that you can trust. Our Quality Management System ensures that we keep our Eye on Quality and provide you with the products, services and solutions you need for your mission critical and business critical applications. Processes have been established across the organization to drive quality efforts:

▩ Develop qualitative and quantitative measurements n Identify improvement opportunities

▩ Provide resources for continual improvement

▩ Empower organizations to make improvements

▩ Monitor indicators and drive improvements across the organization

All Talkpod employees are expected to perform to the absolute best of their abilities to offer you the quality you expect from your preferred solution provider. Each of us strives to keep our EYE ON QUALITY and become your TRUSTED PARTNER.

TRUSTED QUALITY

Contact Us